|

[?]Subscribe To This Site

|

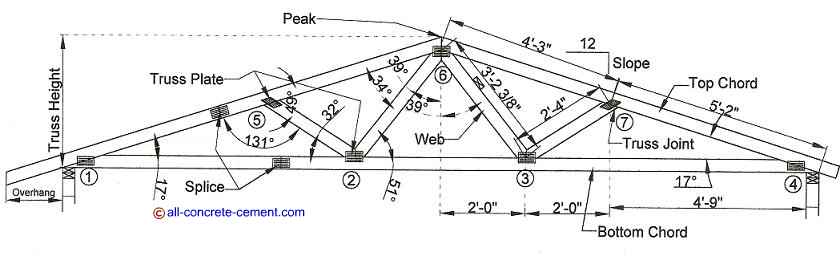

Steel Roof Truss DesignThe steel roof truss design discussed in this page is the same procedures used in calculation roof trusses for wood building roof trusses design and analysis. Even the joint method of analysis used in build your own roof truss can be used to determine the member forces for metal roof trusses which is necessary to build a common roof truss. These procedures are not only important for design but roof truss prices as well. The truss diagram below is the same truss used in the truss analysis per calculation roof trusses for wood frame. In this discussion, we will look at the same truss only to be steel framed. The biggest difference between woof frame and steel frame is the truss spacing, for wood deck 7/16 inch wafer board is 2 ft on center for trusses, for steel one and a half inch metal deck 20 gauge can span up to 5ft.Roof Dead Load Calculation: The truss assume to be all angles L3x3x1/4 weighs 4.9 lbs/ft The truss top chord, bottom chords, and webs are of L3x3x1/4 that weighs 4.9 lbs/ft. Adding up all the truss members comes out to a total length of 47.5 ft – truss weight = 4.9x47.5 = 232.8 poundsMetal deck = 2.16 psfCeiling = 1.7 psfRoof = 2.4 psfTruss = 2.7 psf [232.8/(17.5’x5’)] Total Dead Load = 8.96 psf

Live Load Calculation: Per code roofs need to be designed for minimum load of 20 psf. Even if you are in areas that are not affected by snow, roofs still need to be able to withstand maintenance crew and workers for roof installation. In areas affected by snow roofs are designed Snow Loads of 30 or 40 psf which are over the minimum design load. In this case we are going to use LL = 20 psf The total load = 20 + 8.96 = 28.96 psf times 5 ft on center, truss spacing = 144.8 plf all applied at top chord. At the bottom chord, one layer of drywall is hung drywall from the bottom chord:DL bottom chord: 1.8 psf For continuation of this click here. Back to steel roof trussdesign |

|